Ventia has served Transpower for more than 30 years with successfully continuing contract renewals. Today we currently service 37 per cent of Transpower's network; Our success reflects a commitment to achieving client satisfaction and driving ongoing innovation.

Client

Project duration

| Commenced: 1992 - Current

Description

Ventia is responsible for maintenance, construction and asset management across Transpower's network. This incorporates the following services:

Transmission lines

- Patrols, routine maintenance, condition assessment, defect correction, vegetation control and upgrade projects associated with 40 per cent of Transpower’s 11,800km transmission line network

- Asset management services, conducting line route patrols, site inspections including computer analysis, condition assessment reporting, ongoing landowner and utility liaison and negotiation, vegetation advisory service

- Regular inspections, preventative and routine maintenance, identification and execution of non-routine work including defect correction and equipment replacement projects

Construction services

- Establishment of site access, vegetation clearing and protection of line route, site civil and foundation works, tower construction, pole construction, conductor/cable stringing (including OPGW), retrofitting of line hardware

Core grid substation assets

- Performing all routine inspections and associated maintenance activities of 58 x 220kV and 110kV substations, including the transformers, line, feeder and bus zone circuit breaker (CB) fail protection assets. 50% of Transpower revenue metering sites

- The maintenance and project works for New Zealand’s only high voltage direct current (HVDC) link station. This includes the synchronous condensers rotating the valve stacks and SVCs

- Refurbishment and life extensions of 220/110kV power transformers and SF6 circuit breakers. The configuration and maintenance of SCADA and remote terminal unit devices, including the main trunk communications networks supporting these systems

- Medium and large substation refurbishment projects including the replacement of buildings and foundations, new primary and secondary assets, new HV and MV cables. In many cases these are brownfield upgrades requiring comprehensive planning and commissioning documentation and can run over multiple years

- 24-hour emergency response services.

Scope of work

- Transmission line inspections and maintenance

- Capital works across the transmission network

- Substation services

Project outcomes

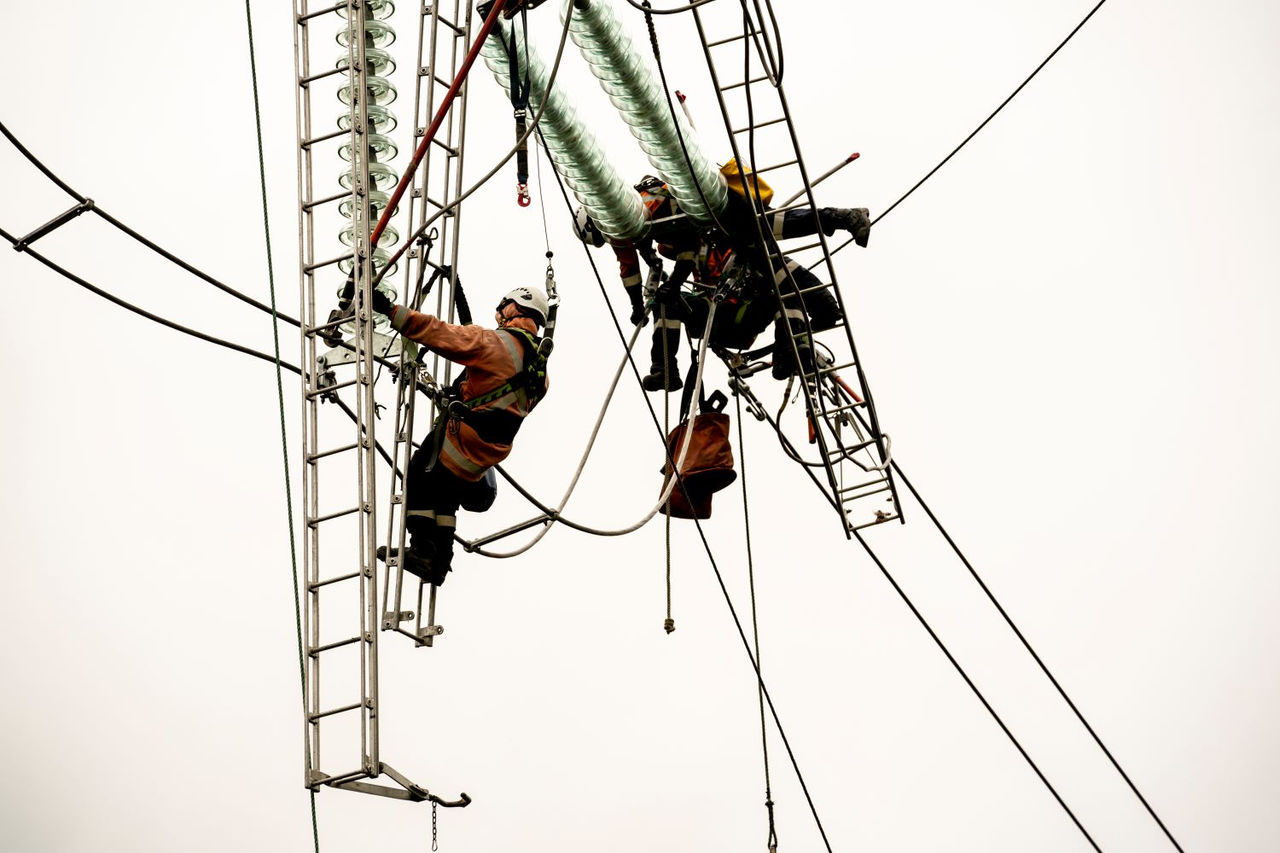

Live line techniques

Ventia has an ongoing commitment to the development of live line techniques, an example of which has been the development of a live-line conductor trolley. These specially insulated trolleys, believed to be the first of their type in the world, allow spacer replacement to be cost-effectively undertaken without disruption to supply. Our reputation as a leader in the use of advanced technology was also confirmed through a technique pioneered to reduce damage to transmission lines and improve line security. During high winds or when snow and ice accumulate, individual conductors on a transmission circuit may clash, resulting in power outages. To prevent these clashes, we installed fiberglass interphase spacer rods using a new technique which was a first for New Zealand. The technique involved two-line mechanics seated in vertical configuration, beneath a Bell Iroquois helicopter in purpose-built chairs. Their objective was to connect both ends of three-metre-long rods to the conductors.

We consulted with Civil Aviation and Occupational Safety and Health professionals early in the approval process and the procedure complied with all requirements.

Drones inspect high-risk assets

We visit and inspect more than 11,500 transmission towers as part of our electrical maintenance contract. Some of these towers are located in tough terrain and only accessible by foot, and then our employees are required to climb several metres up the transmission tower to conduct the inspection. Drones can eliminate the likelihood of a manned aircraft coming in contact with lines and towers during routine visual inspections, improving overall health and safety. Transpower’s new unmanned aircraft are equipped with multiple fail-safes, including self-deploying parachutes, in the event a flight should unexpectedly terminate. Using drones also minimises the number of helicopter flights required for visual inspections of assets. The transition away from helicopters for this type of work will reduce the noise and inconvenience currently experienced by tens of thousands of people living under or near Transpower’s lines.

The unmanned aerial inspection is more cost effective, efficient and safer than before, and it picks out multiple defects that wouldn’t have been detected from the ground.

Image gallery

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

Statistics

Awards

- 2024

- 2023

- 2022

- 2021