We've been working with Transpower for more than 25 years, but we still know how to do things that continue to raise the bar with our service delivery.

We're thrilled to have been recognised as finalists at Transpower's inaugural Engineering and Technology Excellence Awards!

We were recognised across two categories for our commitment to the future of the industry through our ongoing investment in our oil lab and for completing a complex and challenging upgrade project within an unprecedented timeframe using innovative new methods.

Our team was recognised for continually raising the bar and investing in the oil testing laboratory.

Investing in the future through our oil lab (finalist)

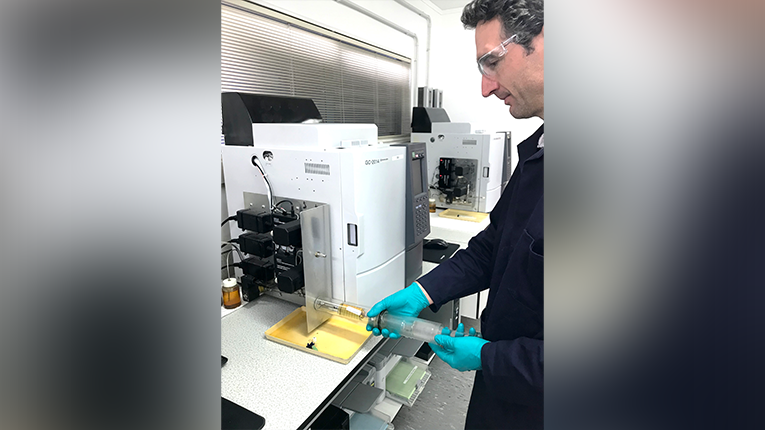

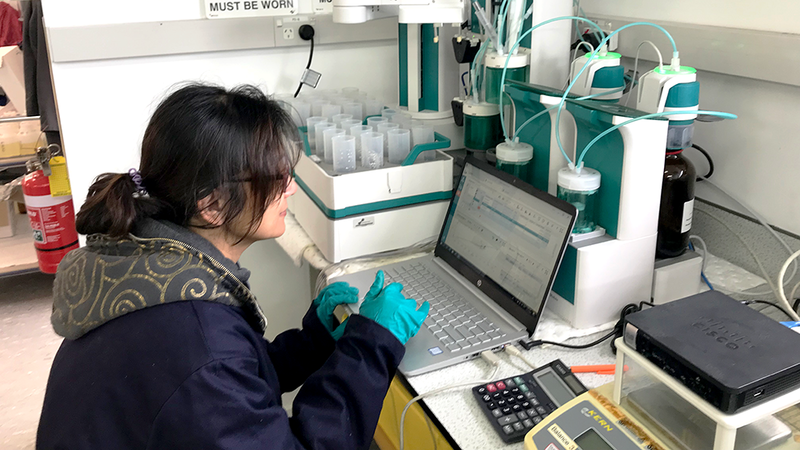

Ventia's oil laboratory has been servicing New Zealand's high voltage and distribution industry since 1987. The facility, which has IANZ ISO 17025 certification, specialises in the testing and analysis of insulating oils for high voltage equipment. Testing of oil is critical in transmission as it provides a highly accurate indication of the internal condition of a transformer and is therefore a critical element of reliable energy transformation.

Our team was recognised for their commitment to continually raise the bar and invest in the oil testing facility, providing our clients with the necessary reliable information to manage their electrical assets.

The upgrades have included automation technology to improve efficiency and safety controls, it has also allowed for Ventia to provide quicker turnaround in providing results to clients.

The upgrades to the laboratory have included automation technology to improve efficiency and safety controls.

A key feature of the upgrades has been the consultation and collaboration with clients and partners.

The benefits extend beyond the above, with our team also focusing on sustainability through the planned introduction of more sustainable materials such a glass or aluminium sampling bottles (as opposed to plastic).

With the upgrades Ventia now has a facility that features the latest in testing technologies and procedures, aligned with international best practice.

In Wellington, our team needed to complete an important upgrade whilst minimising power outages.

Innovation during upgrade at Judgeford (finalist)

Faced with a challenging project in Wellington New Zealand, our team needed to complete an important upgrade whilst minimising power outages across major populated areas.

Collaborating with our client Transpower the team utilised leading-edge software and protection test equipment to implement an innovative new method which ultimately reduced outage duration by 40%.

The key innovation was the use of end-to-end system-based testing, using OMICRON's RelaySimTest. This enabled pre-testing of all protection functionality, SCADA checks and communications paths. Traditionally, this sort of testing would need to be completed during the outage. By using the pre-testing method, the outage protection time (period when risk of outage is higher) was reduced by 40%.

While the impact on the Judgeford project was significant at a project level, the flow on impact for future work is even greater. Having proven the system, Ventia are now looking at opportunities to apply this technology across our protection testing and commissioning as the default method.

Ventia has been working with Transpower for more than 25 years and continues to raise the bar for delivering service excellence.